Services Provided

Our expert services and equipment offer project efficiency, reducing time lines, environmental pollutants and destruction. Eliminating to and from site traffic and the need to destroy virgin ground. Our decades of experience allow us to effectively and efficiently make use of materials on-site. Each project is unique, our approach to each project is as well. NRC processes a variety of materials on location into a salable and reusable product. We are focused and committed to our clients’ needs, projects’ goals and specific requirements. Delivering an Eco-friendly and client driven service and product. We are the northeast’s solution for rock crushing and recycling services.

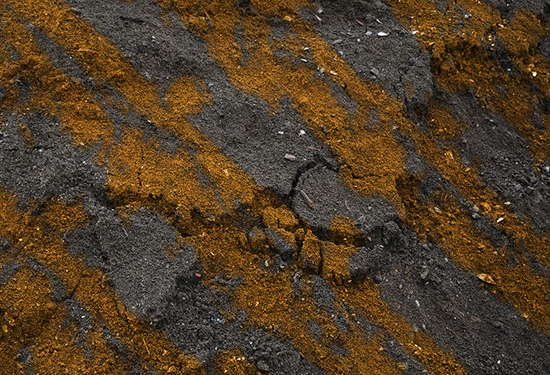

Asphalt Recycling

Recycled Asphalt is processed to produce RAP (recycled asphalt product). Old existing asphalt use to be viewed as waste material. Recycled bitumen along with high quality aggregates can be processed into a feed material. RAP can be reused as top dressing for drives and parking lots. An effective alternative to traditional asphalt. Asphalt recycling significantly reduces energy consumption and keeps these materials out of landfills. A budget friendly product with a greatly reduced impact on the environment. RAP is proven to be an effective alternative. Environmental Practices are increasing each year.

Asphalt is nearing 100 million tons being recycled annually. NRC produces RAP from old asphalt at a high rate efficiently, reducing pollutants and time. Our highly qualified professionals offer an unmatched level of service. We are committed to providing you the material you require, where and when you need it.

Clay Brick Crushing

Demolition projects involving the removal of brick and mortar structures use our services as an end solution. Construction & Demolition Waste (CDW) recycling has grown over that past decades. Recycling clay brick waste material into a usable and sell-able product instead of filling up landfills and yards already overtaken by waste material. Crushed Clay Brick (CCB) can be processed into a chip based product. Some concrete mixes will make use of CCB as a substitute to lessen the consumption of aggregate.

Crushed Clay Brick

Has a variety of obvious environmentally beneficial uses. Popular in the landscaping industry as a low maintenance product that also offers superior longevity compared to alternative landscaping materials. A sustainable product being used in both commercial and residential landscape design. With an increased use of CCB in walkways, drives and flower, shrub and tree gardens. We provide a safe and economical solution for one the most available demolition materials.

Concrete & Concrete with Rebar

Waste Concrete when recycled is known as RCP (recycled concrete product). Utilized for a superior sub-base material. This end product provides an extremely high strength aggregate for new concrete or use for a variety of applications. Separating steel from cement. This process also helps minimize or eliminate demolished concrete waste and disposal costs. Just like all recycling approaches, RCP is an environmentally safer alternative and cost effective solution.

Our processing capabilities allow us to process concrete aggregate with and without rebar effectively no matter the amount of steel. The reuse of RCP for sub-base, riprap, gabions, and landscaping is beneficial in many ways. The use of construction aggregate has reached close to 50 billion metric tons world wide. The reuse of construction waste & demolition waste is essential to a cleaner environment, while also proven to be cost effective. Northeast Rock Crushing is an expert concrete, with or without, steel processing company.

Rock & Aggregate

Northeast Rock Crushing has the capability to crush rock, produce aggregates and utilize many other valuable raw materials efficiently and effectively. Using crushed aggregate from your site instead of relying on material brought in from virgin ground or processed off-site is not only cost effective, but is also less damaging to the environment. NRC processes some of the most difficult material into a usable product on-site. This clean processed material can be used as sub-base, substrate, back fill, utility trenches, landscaping and more.

Eliminate the export process of excess rock or burying large rocks on-site. Our engineering department takes material samples from project sites to evaluate and determine the most efficient processing approach. It is our focus to ensure that your project’s goals and time lines are met. That all of your contractors are provided with the material they need, when they need it. Our company’s long developed on-site work flow sets us apart from our competition. Our reputation has been hard earned over the years through the high degree of commitment and dedication we offer. Providing a superior level of experience and service, on-site and on time.

Screening

The usability and saleability of our processed material is dependent upon the uniformity of the crushed material being processed. NRC provides high quality, consistently sized product materials that meet your particular needs and specifications. Materials screened consist of rock, gravel, concrete, sand, and more. Our knowledge and experience provides you with the service and product that you require.

Consistency and uniformity. Our professional equipment ensures that the end product we provide meets your requirements. Our equipment is meticulously and consistently maintained. Our screening equipment reprocesses material until it meets the targeted size. NRC provides a clean and uniformed end product.

Mixed Material Processing

Excavating and Landscaping Companies with excess project material are typically not equipped with the necessary equipment or experience operating material processing machinery. We come to you, offering the same solutions to projects large or small. Processing thousands of tons per day on-site helping turn your excess project material into a salable product with our untouchable services, commitment and competitive rates.

Our on-site rock crushing and recycling plant makes quick use of mixed material, converting it into a clean usable material. Producing product to meet required specifications for project development or a salable product for construction and landscaping companies with yards overtaken by project material.